Ultimate Guide to Hydraulic Pump Volvo: Boost Your Heavy Machinery Performance

In the realm of industrial machinery, construction equipment, and heavy-duty vehicles, the hydraulic pump Volvo plays an essential role that cannot be overstated. This powerful component is the heartbeat of hydraulic systems, enabling precise control, efficient force transmission, and reliable operation of equipment ranging from excavators to cranes. Understanding the intricacies of hydraulic pump Volvo, its importance, and best practices for maintenance and selection can significantly influence the productivity, longevity, and operational cost of heavy machinery.

Understanding the Role of Hydraulic Pumps in Heavy Machinery

Hydraulic pumps are pivotal in converting mechanical energy into hydraulic energy—producing fluid flow that powers hydraulic cylinders, motors, and other components. Among various brands, Volvo has emerged as a leader in manufacturing high-quality hydraulic pumps specially designed for durability and efficiency. These pumps are engineered to withstand harsh conditions, delivering optimal performance in demanding environments.

Why Choose a Hydraulic Pump Volvo? The Brand's Edge

When considering hydraulic pump Volvo, several aspects distinguish Volvo from its competitors:

- Reliability and Durability: Volvo hydraulic pumps are constructed with high-grade materials and precision manufacturing, ensuring long service life even under strenuous conditions.

- Efficiency: Designed for minimal energy consumption, Volvo pumps deliver maximum flow with optimized pressure control, resulting in lower operational costs.

- Compatibility: They integrate seamlessly with a variety of Volvo machinery and are adaptable to suit custom needs in different applications.

- Innovative Technologies: Incorporation of advanced hydraulic technologies enhances performance, reduces noise, and promotes smoother operation.

Components and Types of Volvo Hydraulic Pumps

Understanding the various types of hydraulic pumps Volvo manufactures can help in selecting the right component for specific machinery. The primary types include:

Gear Pumps

Gear pumps are the most common and simple hydraulic pumps, ideal for low-pressure applications. They operate using intermeshing gears that create a vacuum to draw hydraulic fluid and push it through the system. Volvo gear pumps are known for their robustness and straightforward operation.

Piston Pumps

Suitable for high-pressure systems, piston pumps utilize reciprocating pistons to generate flow. Volvo piston pumps are celebrated for their efficiency, high flow capacity, and excellent handling of demanding workloads, making them perfect for excavators, loaders, and heavy-duty industrial machinery.

Axial Piston Pumps

These pumps provide variable flow and pressure control, essential for applications requiring flexible performance. Volvo’s axial piston pumps incorporate advanced design features that ensure precise control and smooth operation, reducing wear and tear over time.

Choosing the Right Hydraulic Pump Volvo for Your Equipment

Selecting the optimal hydraulic pump Volvo involves understanding specific operational requirements and compatibility factors. Here are crucial considerations:

- Flow Rate: Determine the volume of hydraulic fluid required per minute to meet machinery demands.

- Pressure Needs: Assess the maximum operating pressure the pump must withstand without failure.

- Application Type: Heavy lifting, precise control, or high-speed operations necessitate different pump types.

- Ease of Maintenance: Opt for pumps that allow straightforward servicing and have readily available spare parts.

- Compatibility with Existing Systems: Ensure the pump fits seamlessly into your hydraulic circuit without requiring extensive modifications.

Maintaining Your Hydraulic Pump Volvo: Tips for Longevity and Efficiency

Proper maintenance extends the lifespan of your hydraulic pump and guards against costly downtime. Follow these best practices:

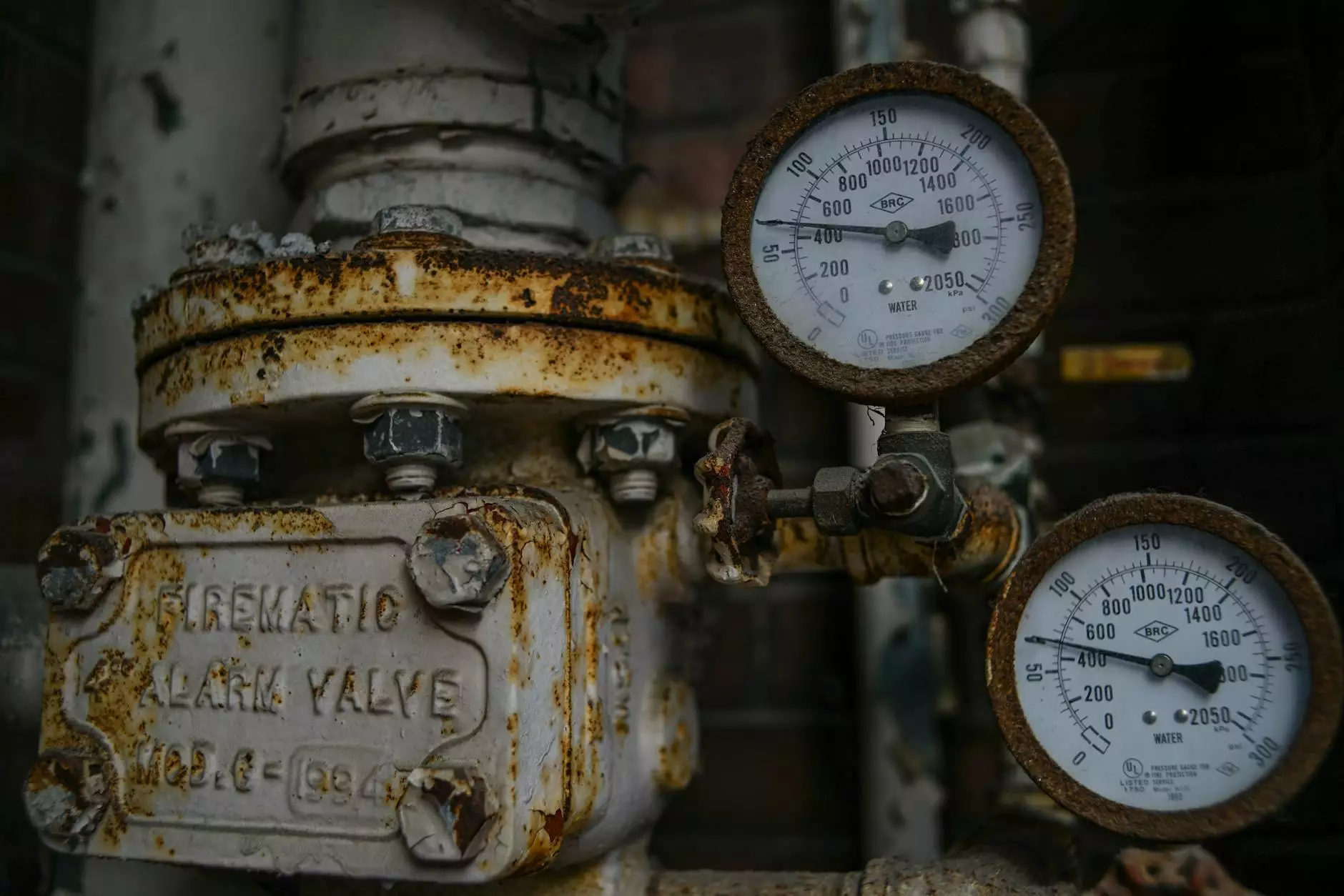

- Regular Inspection: Check for signs of wear, leaks, or damage. Early detection prevents failure.

- Fluid Quality: Use high-quality hydraulic fluid recommended by Volvo, and replace it as per the manufacturer's schedule.

- Filter Maintenance: Keep filters clean to prevent contamination that can damage internal components.

- System Pressure Checks: Monitor operating pressure regularly to ensure it remains within stipulated limits.

- Component Alignment: Ensure correct alignment and secure mounting to avoid undue stress on the pump.

Common Problems with Hydraulic Pumps and How to Address Them

Even the best pumps can encounter issues. Recognizing symptoms early can prevent further damage:

- Loss of Hydraulic Pressure: May result from internal wear, leaks, or blocked filters—address by inspection and repair or replacement.

- Unusual Noise: Indicates cavitation or air entrainment; check fluid levels and eliminate air from the system.

- Overheating Pump: Caused by excessive demand or poor lubrication—ensure proper fluid temperature and cooling mechanisms.

- Fluid Leaks: Often from seals or fittings—replace worn seals and tighten connections.

Where to Source Genuine Hydraulic Pump Volvo Parts

For maximum performance and reliability, always opt for genuine Volvo hydraulic parts. Reliable sources include authorized dealerships and specialized suppliers such as shophydraulicamerica.com. Ensuring the authenticity of parts guarantees compatibility, durability, and access to technical support.

Integrating Hydraulic Pumps into Heavy Machinery Maintenance Plans

Implementing a comprehensive maintenance schedule specific to your hydraulic pump Volvo enhances operational efficiency. Regular servicing, timely replacements of filters and fluids, and monitoring system parameters form the backbone of preventative maintenance strategies.

The Future of Hydraulic Technology and Volvo Innovation

Volvo continues to lead with innovation, integrating digital monitoring systems, eco-friendly hydraulic fluids, and energy-efficient pump designs. These advancements not only improve performance but also contribute to sustainability efforts within the heavy machinery industry.

Additional Resources for Optimal Hydraulic System Performance

- Training and Certification: Educate your maintenance team on hydraulic system care for better results.

- Technology Adoption: Use diagnostic tools to monitor pump performance remotely and prevent failures.

- Supply Chain Reliability: Partner with authorized suppliers like shophydraulicamerica.com for genuine parts and expert support.

Conclusion: Elevate Your Machinery with Quality Hydraulic Pumps

Choosing the right hydraulic pump Volvo is fundamental to ensuring your heavy machinery operates at its peak capability. With their celebrated durability, efficiency, and technological innovation, Volvo hydraulic pumps are a smart investment that boosts productivity, reduces downtime, and lowers long-term operational costs. Remember, pairing high-quality components with diligent maintenance and timely servicing paves the way for long-lasting machinery performance.

Explore our extensive selection of auto parts & supplies and motorcycle parts & supplies at shophydraulicamerica.com and ensure your equipment is equipped with genuine Volvo hydraulic components. Elevate your business operations with the confidence that comes from premium quality parts and superior expertise.

Contact Us for Expert Guidance and Superior Hydraulic Components

Looking for tailored advice or specific hydraulic pump Volvo solutions? Reach out to our specialists at shophydraulicamerica.com. We are committed to helping you find the perfect parts to match your machinery's unique requirements, ensuring top performance and reliability.